Meat and poultry Solutions

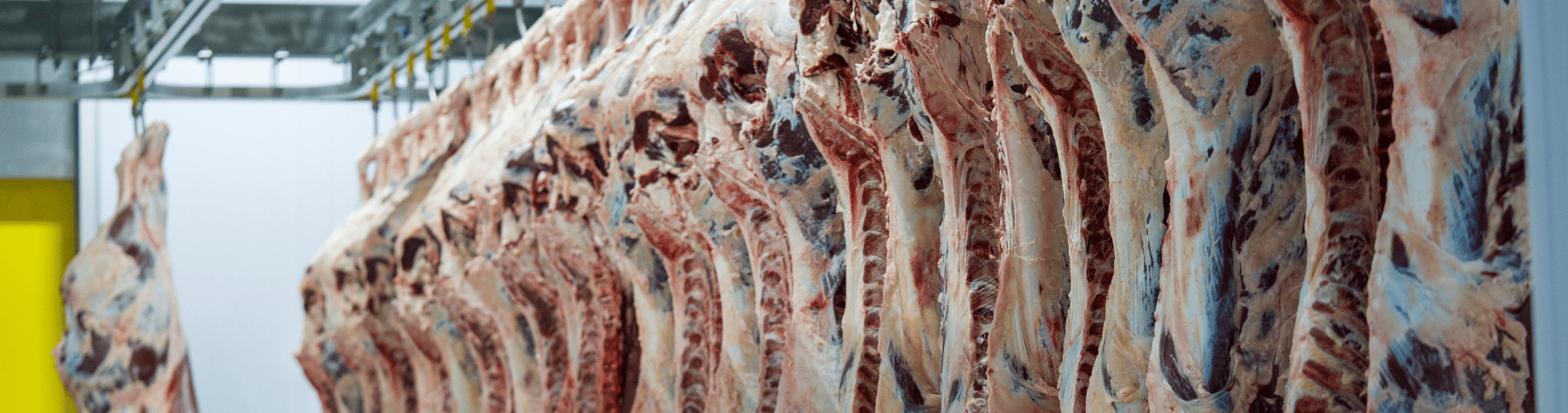

The meat and poultry industry’s primary mission is to provide consumers with a safe, nutritious, and high-quality protein source. Achieving this requires strict adherence to safety standards, innovative solutions, and operational efficiency. Hydrite provides processors with resources to make this mission a reality by delivering advanced chemistry and tailored programs that address the unique challenges of meat and poultry production. Our solutions go beyond products; we provide expertise, technical support, and continuous improvement strategies to ensure compliance, enhance product quality, and optimize processes.

Hydrite programs are designed to optimize food safety, improve yield, and reduce operational costs, resulting in greater profitability and sustainability. By implementing robust sanitation and antimicrobial strategies, we help minimize contamination risks and extend shelf life, while streamlining workflows to reduce downtime and resource consumption. These benefits not only protect your brand but also foster long-term business relationships built on trust, reliability, and innovation. Solutions Hydrite offers include:

- Sanitation

- Intervention Chemistry

- Water Treatment

- Production Chemistry

- Commodities & pH Adjusters

- Foam Control

- Multifunctional Ingredients

![]()

Sanitation

Your plant sanitation has a direct impact on product shelf life and maximizing your production capacities. Sanitation also impacts effluent costs, employee safety, and the life of your equipment, all of which could be improved through a relationship with Hydrite. We produce a complete line of detergents and sanitizers for the meat and poultry industries including:

- Foam Cleaners

- Spray & CIP Sanitizers

- Manual Cleaners

- Smokehouse Cleaners

- Process Oven Cleaners

- Cook Kettle Cleaners

- Membrane Cleaners

- Single Phase Cleaners

- Doorway Foot Foamers

- Hand Sanitation Products

- Environmental Sanitation Programs

Intervention Chemistry

Conditions that encourage bacterial growth risk the proliferation of food borne pathogens such as E. coli, Listeria, and Salmonella. To decrease your risk for these pathogens and improve consumer safety, Hydrite has the expertise in meat and poultry intervention chemistry you need.

Spraying/Dipping

-

Carcass Wash Applications

Antimicrobial Interventions

Equipment

- Hydri-Vision: Auto Titrator

- Belt & Conveyor Applications

- Water Reuse System

- Water Inject System

Water Treatment

Wastewater treatment creates special challenges associated with BOD, fats and oils, greases, suspended solids, phosphate reduction, and odor control. The wastewater treatment specialists at Hydrite are experienced in helping our customers manage the aforementioned issues while remaining in compliance with local regulatory restrictions. We have a complete line of chemicals for wastewater treatment such as:

- Acids & Caustic for pH Adjustment

- Coagulants for Clarification

- Polymers & Flocculants for Liquid/Solid Separation

- Phosphorus Reduction Compounds

- Bisulfites for Dechlorination

- Odor Control Compounds

- BOD/Solids Reduction

- Bioaugmentation

- Membrane Cleaners

Production Chemistries

Meat and poultry companies rely on chemicals to keep their operations running smoothly during production. Hydrite has a complete line of production chemicals and creative chemical feed technology to provide consistent results, eliminate downtime, and control your operating costs.

- Carcass Wash

- Trolley Cleaners & Lubricants

- Tripe Wash & Bleach

- Hog Scald Compounds

- Chiller Water Treatment Products

- Denaturants

- Feather Cleaners & Brighteners

- Rendering Department Products

Commodities & pH Adjusters

In addition to being a leading manufacturer of plant sanitation chemicals, Hydrite is also one of North America’s largest chemical distributors. Our purchasing power means savings for our customers. We can supply your needs, in bulk or packaged sizes, across a wide variety of commodities including:

- Caustic

- Chlorine – Gas & Liquid

- Muriatic Acid

- Phosphoric Acid

- Sulfuric Acid

Foam Control

A lack of proper foam control can slow your production and create serious wastewater treatment issues. Hydrite manufactures a full line of defoamers to address those needs. We offer silicone and non-silicone-based food grade defoamers to keep your poultry chillers and blood plasma operations running smoothly. We also offer CIP and wastewater defoamers along with the associated feed and control equipment to ensure economical operation.

Rendering

Rendering is a vital process that transforms animal by-products into valuable materials like fats and proteins, helping reduce waste and support sustainability. Common challenges in rendering facilities include odor control, sanitation, pest management, and effective wastewater treatment. Specialized chemicals and equipment are used to maintain hygiene and environmental compliance while maximizing the utility of non-edible animal parts.

Hydrite works side by side with you to find creative solutions to meet the strict standards accompanying your product formulations. You can depend on us for reliable, high quality food ingredients to help you meet your customers’ expectations.

Applications & Opportunities

- Multifunctional ingredient blends for protein modification and improved moisture retention

- Liquid acidulant systems tailored by concentration

- pH buffering systems for optimizing processing

- Pathogen control with lactate blends

- Proven food safety sanitation programs

Meat & Poultry Ingredient Examples

- Citric Acid

- Citric Blends

- Phosphates & Phosphate Blends

- Lactic Acid

- Lactate Blends

- Anti-coagulants

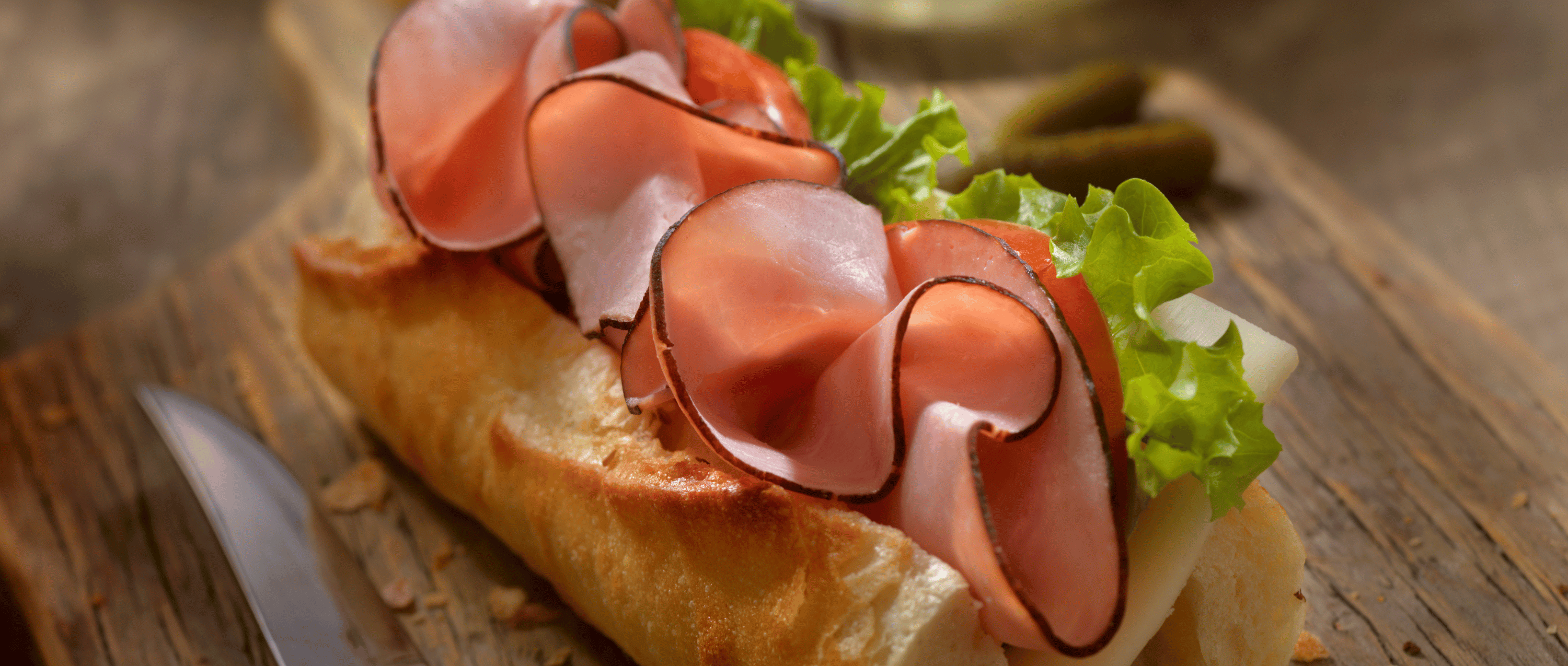

Ingredient Spotlight: Potassium Lactate in Pork Processing

Hydrite’s potassium lactate is a multifunctional ingredient that extends shelf life, enhances food safety, and preserves the color and flavor of pork sausage products. Independent research with Texas Tech University confirms our solution delivers lower spoilage bacteria, improved oxidative stability, and superior sensory appeal—making it the smart choice for meat processors and brands focused on quality and consumer satisfaction. Request full access to the study to learn more:

Service and support

At Hydrite, we take the time to understand your evolving needs, because your success is our priority. Our team brings deep industry knowledge and a creative approach to solving challenges that impact your profitability. We’re passionate about delivering exceptional customer service and committed to helping your employees succeed through hands-on training and support.

Our goal is to help you consistently achieve high-quality, reliable results at the lowest possible cost. Many of our technical and service professionals come from food production backgrounds, giving them the insight and experience to help you run your process as efficiently as possible.

Engineering and Equipment

Properly engineered chemical allocation systems can help increase the safety of your employees and reduce lost time due to accidents. Additionally, these systems provide accurate and cost-effective chemical use, keeping wastewater treatment costs at a minimum. Our knowledgeable service team can consult on:

- Detergent Feed Systems

- Bulk & Tote Chemical Storage & Transfer

- Central Sanitizing Systems

- Foam Cleaning Equipment

- Central Doorway Foaming Systems

- Liquid Ingredient Storage & Feed Systems

- Hydri-Vision Equipment

Regulation of Chemicals Used for Meat and Poultry Processing

Understanding the chemicals used in food processing and how they’re regulated isn’t just a technical necessity; it’s a strategic imperative for industry professionals. This concise overview reveals the distinct roles of cleaners, sanitizers, processing aids, and hand sanitizers, while unpacking the regulatory landscape shaped by the EPA, FDA, and FSIS. From EPA-registered sanitizers to FDA-defined processing aids and FSIS directives, each chemical type carries unique compliance implications.

Hydrite Training

Hydrite offers training and educational programs to help increase your knowledge and understanding of food safety, and improve your company’s operational efficiencies. Our programs cover topics such as cleaning dynamics, CIP verification & validation, food microbiology, and preventative sanitation - just to name a few. An effective food safety program will enable your company to apply these techniques to everyday working operations and effectively uphold food safety practices. Grow your knowledge with Hydrite

Steve Tienvieri

Senior Lead Microbiologist

26+ Years of Experience

Joel Cook

Senior Technical Manager

22+ Years of Experience

Glen Giersch

ATS Program Manager

28+ Years of Experience

Carl Garcia

Membrane Technical Manager

30+ Years of Experience

Technical Expertise at Your Fingertips

The RITE Team® is a group of experienced professionals tasked to help food processing companies address critical issues through innovative, sustainable solutions. This unique network of individuals includes decades of experience in microbiology, membranes, CIP performance, product selection, equipment, and troubleshooting. The RITE Team® is ready to support meat and poultry processors through technical training, program development, and adjacent technology. Meet the Team

Contact Us

Connect with a Hydrite representative to learn more about meat & poultry solutions for your production facility.