Membrane Technology Solutions

Next Generation Chemistry & Sustainable Chemical Engineering

We focus on developing new products that help our customers improve cleaning efficiency and enhance their total system performance. Our chemists work to develop new and improved products to offer the latest technology in phenol free products and products that help reduce environmental impact. Product Selection Guide

Customized Programs for Facility Protocols

Every plant is unique and cleaning protocols must be customized for each location and application. Our team of experts help you to select the right chemicals and services designed to implement and maintain effective membrane cleaning protocols in your facility and protect your investments.

Membrane Technology Brochure

Adding Value Through Innovation

![]()

Chemistry

![]()

Water

![]()

Time

![]()

Energy

Hydrite Membrane Sanitation Program

This program represents many years of research and development. We’ve listened to our customer's concerns regarding membrane sanitation, and understand the impact your membrane processes have on throughput and productivity. Our objective is to clean the membrane effectively and quickly, to keep your process running smoothly. Our program includes not only a family of detergent and cleaning products which provide superior performance and cost effective cleaning, but also best-in-class technical support, in-plant service, training, and dispensing equipment.

The Hydrite membrane team is prepared to visit your plant to evaluate current operating conditions, cleaning practices, and plant specific objectives. We will then provide detailed recommendations to help meet your objectives and minimize your chemical expenditures, energy, water & effluent charges. Hydrite offers a state of the art membrane chemical delivery system that provides filtration accuracy and proof of delivery.

Next-Generation Enzyme Program

ELEVATE NO. 338

Elevate No. 338 is a buffered alkaline product specifically for use with enzymatic cleaners to maintain optimal pH during cleaning. For use on reverse osmosis, nanofiltration, ultrafiltration and microfiltration membranes.

ARCADIA NO. 314

Arcadia No. 314 is a neutral, liquid cleaner that contains stabilizing surfactants and concentrated enzymes for use on reverse osmosis, nanofiltration, ultrafiltration and microfiltration membranes.

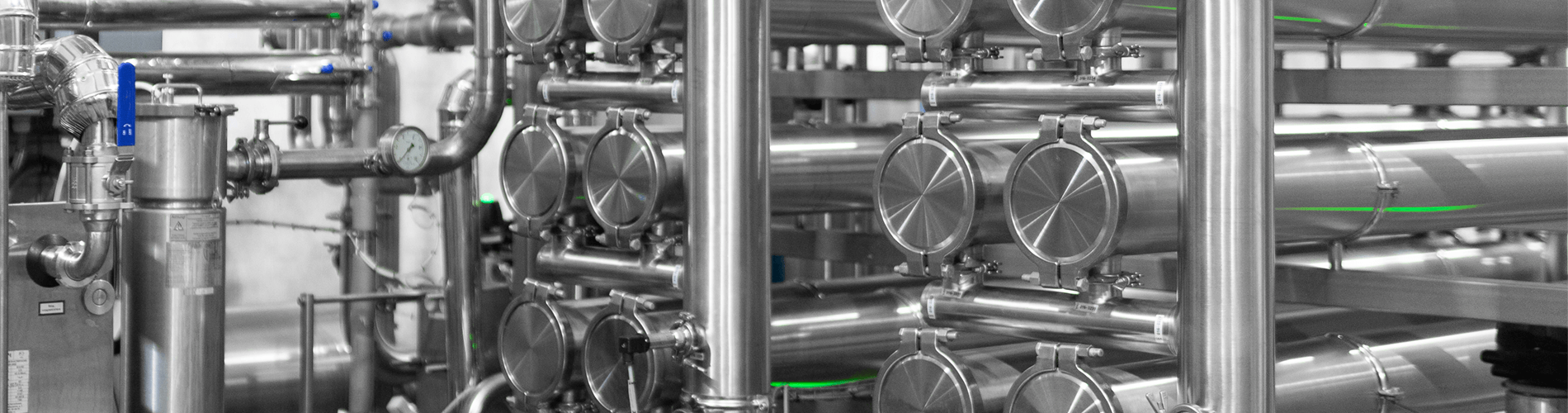

Where is Membrane Technology Used?

Membrane technology plays a vital role in many environmental and industrial processes. In many cases, membranes are used to treat or filter water, but they can also be used in energy production, resource recovery, and pollution control. Whatever the application, membrane sanitation and cleaning is necessary, and the efficiency of these processes impacts a company's overall productivity.

Hydrite offers a full range of services designed to implement and maintain effective chemical membrane cleaning protocols in your facility. Our sanitation offerings extend from effective detergents to in-plant support and training, ensuring that you not only receive the right chemical products but that your employees use them properly.

The Membrane Separation Process

Because membranes are useful for filtration and separation, they hold value for clients in diverse industries. Common industries include:

- Food and beverage

- Wastewater treatment

- Waste and recycling

- Energy, oil, and gas

- Paints, coatings, inks, and adhesives

While applications vary, the general principles underlying membrane separation remain the same—including the challenges presented by the systems. For instance, concentration polarization is a challenge faced by all separation processes which causes the composition to differ at the feed-membrane interface as compared to the rest of the mixture. While inevitable, this gradient negatively affects performance and failure rate, meaning it must be carefully managed for each individual implementation.

Hydrite has years of experience designing solutions that mitigate such challenges while meeting your own industry's specific requirements and regulations.

Contact Us

Contact us today about our products and services, and get started on your own customized program.