Plant Sanitation Solutions

Customized Approach

We provide a variety of solutions designed to optimize operating costs and improve efficiency. We rely on a consultative problem-solving approach when we work with our customers. Hydrite offers customized programs that align with customer requirements and strategies.

Quality Focus

We take the time to understand your business before suggesting solutions. No matter what it takes, the Hydrite family is dedicated to formulating the perfect solution for your individual needs. We understand how important it is to protect the trust your customers place in you, and we’ll help deliver a quality solution at the best possible cost.

Chemical Expertise

Our team is dedicated to providing technical services that help maximize efficiency and profitability all while maintaining or enhancing the quality of your end product. At Hydrite, we understand the process flow that is unique to your industry. Our training covers everything from the basics on sanitation to highly technical subjects such as CIP design, hydraulics, and food safety.

Product Line

We offer a full range of products—CIP cleaners, acid rinses, sanitizers, and processing aids—used in the food and beverage industry for a variety of cleaning, sanitization, and disinfection applications.

Protect your facility + consumers with a leader in plant sanitation.

Plant Sanitation Process

The plant sanitation process is essential to the safe production of foods and beverages. This process is designed to remove soil, microorganisms, and other contaminants from the manufacturing environment. As such, it plays a crucial role in factory safety for manufacturers of foods and beverages.

At Hydrite, we provide creative solutions specifically designed to address food safety concerns. We also aim to increase operational and equipment efficiency while ensuring complete customer satisfaction. Some of the world's largest manufacturers look to Hydrite for their plant-wide sanitation needs.

Hydrite has the flexibility and technical expertise it takes to produce custom solutions engineered to your unique needs. We leverage our extensive lines of sanitation products with technical support from our staff in order to increase your productivity and your bottom line.

What are the Benefits of an Effective Plant Sanitation Program?

The plant sanitation process offers a host of benefits to plants and consumers alike, such as:

Contaminant Removal

Plant sanitation is crucial to ensuring food safety and quality in environments such as plants working frequently with beef, dairy, poultry, and cheese. Food safety would be unachievable without the removal of pathogenic organisms. When these organisms are not removed, they can form biofilms that compromise facility and product safety.

Product Quality

Sanitation is also critical to food and beverage quality. Spoilage organisms are removed during the process, which helps to improve the shelf life of products. Proper sanitation also aids in preventing residue cross-over from various animal species—this helps prevent flavor impact from cross-over, as well.

Increased Performance

Improved sanitation boosts plant productivity by facilitating smooth start-up and production processes. Manufacturing facilities can also spend less time worrying about regulatory action and more time focusing on actual work. Food and Drug Administration (FDA) and Food Safety and Inspection Service (FSIS) inspectors are much less likely to disrupt day-to-day business at plants that have been properly sanitized.

7 Steps of Plant Sanitation

There are no shortcuts in the sanitation process, especially when it comes to food safety. Learn the seven steps from the dry clean to sanitization.

Silver Dihydrogen Citrate (SDC)

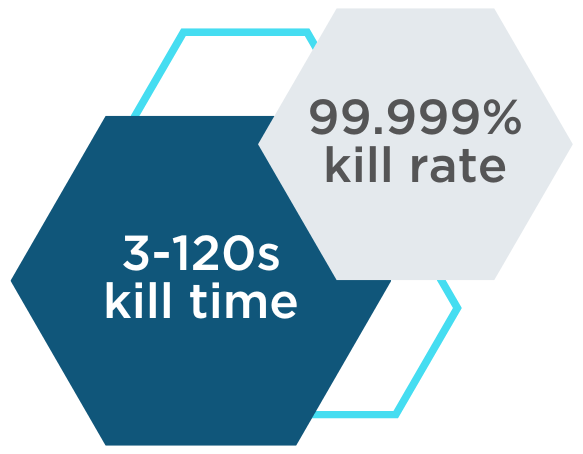

PURE Hard Surface is created for food contact surface sanitization & disinfection. Hydrite is the exclusive distributor of this disinfectant in the dairy and plant-based protein processing market.

Contact Us

Want to learn more about a customized solution for your plant? Contact us today!