Hydrite Academy

Hydrite Academy

Food safety training from an industry leader led by experienced chemists, microbiologists, and technical professionals.

Hydrite Academy: Training the RITE Way™

Training and continuous education is an important aspect of food safety. Ongoing training and everyday application of the food safety principles increase quality and reduce risk while addressing food safety concerns.

Hydrite offers training and educational programs to help increase your knowledge and understanding of food safety, and improve your company’s operational efficiencies. Our programs cover topics such as Cleaning Dynamics, CIP Verification & Validation, Food Microbiology, and Preventative Sanitation - just to name a few. An effective food safety program will enable your company to apply these techniques to everyday working operations and effectively uphold food safety practices.

Food Safety Fridays

FORMAT: Online

LENGTH: 1 hour

Each September we offer weekly, one-hour Food Safety Fridays webinars focusing on food safety and sanitation. These short-form, topical sessions include supplemental information that builds off of our two-day food safety, sanitation, and membrane trainings.

Food Safety, Sanitation & Membrane Training

FORMAT: In-person

LENGTH: 2 days

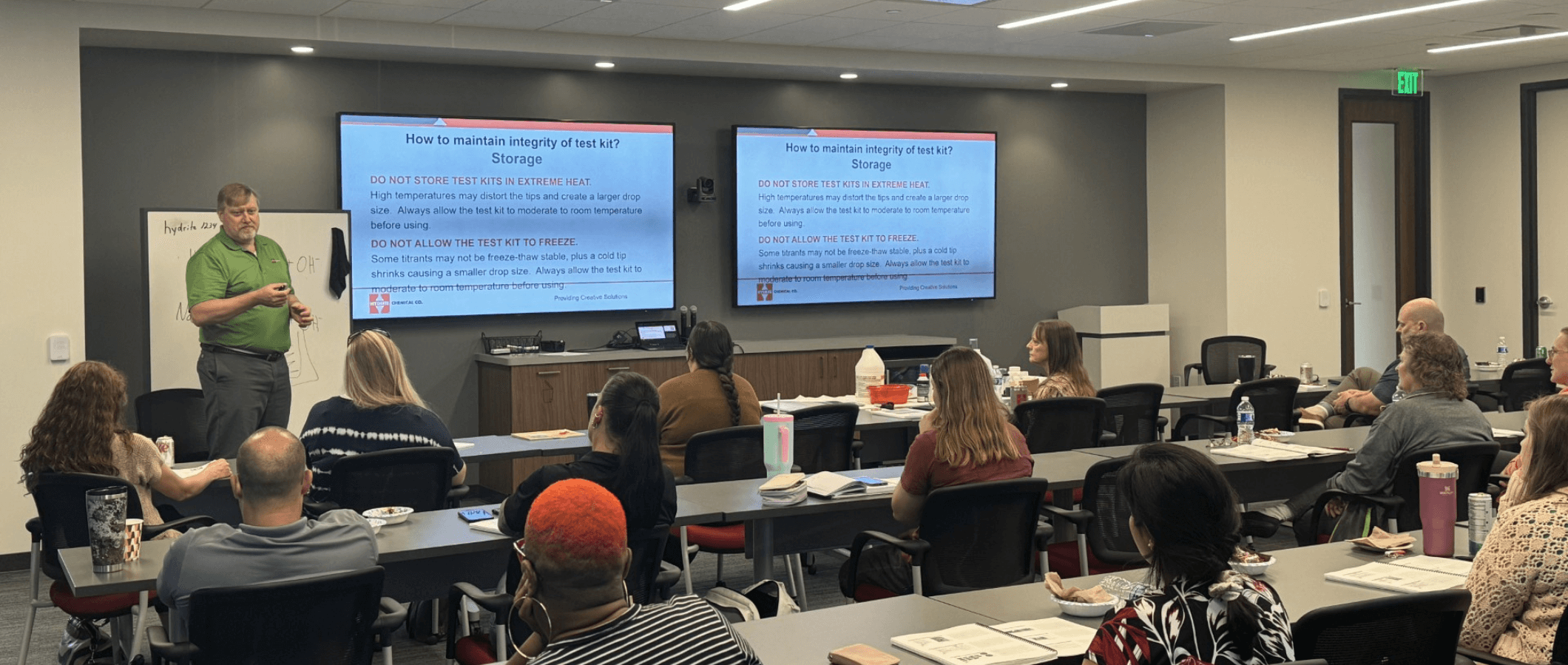

Hydrite’s food safety, sanitation, and membrane workshops equip key food manufacturing employees with up-to-date information and best practices to bring back to the plant. Hydrite takes a comprehensive, creative approach to sanitation and cleaning benefits both processing plants and consumers. Join us for this 2-day event.

FSPCA, PCHF & HACCP Training

FORMAT: In-person

LENGTH: 3 days (Minimum 22 hours)

Food Safety Preventive Controls Alliance (FSPCA) Preventive Controls for Human Foods (PCHF) is a three day course (minimum 22 hours) that will provide the tools necessary to complete the FSMA Preventive Controls rule requirements.

This course, developed by the FSPCA, is the “standardized curriculum” recognized by the FDA. Successful completion of this course meets the requirements for a Preventive Controls Qualified Individual (PCQI). Following the PCHF training is a half-day training for Introduction to Hazard Analysis Critical Control Point (HACCP). This course is designed for individuals who have completed the PCHF course and provides the tools necessary to complete HACCP plans. Individual certificates are provided for the successful completion of these training courses.

This training is available upon request. To discuss options for your facility, please contact us.

Food Traceability Rule Training

FORMAT: In-person

LENGTH: 2 days

The Food Traceability Rule, established under the FDA’s Food Safety Modernization Act (FSMA), aims to enhance the ability to rapidly and effectively trace foods through the supply chain to prevent or mitigate foodborne illness outbreaks. Hydrite’s Food Traceability Rule Training is designed to help food industry professionals understand and implement the requirements of this regulation.

Training Objectives:

- Recognize the importance of the Food Traceability Rule and its role in public health

- Understand the key regulatory requirements and who they apply to

- Learn the steps necessary to achieve compliance

- Practice developing a customized traceability plan for your facility

This training is available upon request. To discuss options for your facility, please contact us.

Our Instructors

Our food safety and sanitation workshops are instructed by members of The RITE Team®, a group of experienced professionals tasked to enhance the technical support in the field to introduce innovative solutions that help address critical issues in the food industry. RITE is an acronym for Real-time, Innovative, Technical, and Expertise. This collaborative team supports our customers and our field to provide technical training, program development, and adjacent technology. Our primary instructors from The RITE Team® are Joel Cook and Glen Giersch.

Steve Tienvieri

Senior Lead Microbiologist

Steve has 26+ years of experience in food microbiology and food manufacturing. His background is extensive and includes Safe Quality Food (SQF), audits, regulatory, environmental monitoring and investigations, Hazard Analysis Critical Control Point (HACCP) and Preventive Controls (PC), and food quality/food safety plan development and employee training. Tienvieri is also a Preventive Controls Qualified Individual (PCQI) certified trainer.

Joel Cook

Senior Technical Manager

Joel has been employed with Hydrite for over 22 years working with the Food, Operations, and Lab Quality Assurance Groups. Joel has presented subject matter at the Membrane Technology Forum, ADPI's Dairy Ingredients 360 Training, and Midwest Food Processors Association.

Glen Giersch

ATS Program Manager

Glen has been with Hydrite for 28 years. Glen is responsible for technical service and field sales support for Hydrite’s Western District. Glen also authored a U.S. Patent for Whey and Lactose Processing Aids for the dairy industry. He has extensive experience in developing sanitation programs and solving sanitation-related issues in the dairy, food, and beverages industries.

Carl Garcia

Membrane Technical Manager

Carl has over 30 years of dairy processing experience. Carl's expertise lies in the membrane technology field. Carl is responsible for membrane system management, training, and implementation. Carl has vast knowledge in membrane chemistry solutions and system operations.

Contact Us

At Hydrite, we care about our customers and appreciate your business. Whether you're inquiring about a specific product, require technical assistance, wish to place an order or simply want to tell us how we are doing, contact us today.