Safety

Since our beginning in 1929, our employees have been the driving force in our success. We put our employees first and work to empower them. We strive to operate in a way that our employees feel safe, valued, and supported while working together to meet our shared goals. A robust safety program is a key part of our culture and permeates throughout our operations.

We track a variety of leading and lagging performance indicators, evaluate risks, implement prevention measures, and plan for current and future initiatives to support our vision of ensuring a safe workplace for everyone at Hydrite. With input from human resources, operations, and recommendations from Hydrite’s Board of Directors, we branded One Hydrite Safety in 2021. This initiative requires our evaluation of individual department and site programs and developing and deploying best practices consistently across the organization.

Examples include prescription safety glasses programs, hearing evaluations, respirator fit testing, contractor management, and partnering with field sales to provide effective personal protective equipment distribution. Even further, improvements have been implemented across departments like ergonomic scrap metal disposal techniques, mobile production floor training technology, and driver/customer collaboration on safe delivery practices.

Safety Vision

Safety is an integral part of the culture at Hydrite. It is our collective responsibility to ensure a safe workplace for everyone at Hydrite.

Safety Mission

Achieve zero incidents and injuries through the continuous improvement of our operational practices and processes where safety remains our top priority.

Safety Values

- I am responsible for my own safety.

- I am responsible for my teammate’s safety.

- I will always wear my PPE.

- I accept feedback about my safety behavior.

- I accept the responsibility to take action when confronted with an unsafe situation.

- I will actively seek and participate in safety improvements.

- I will always follow the Standard Operating Procedure.

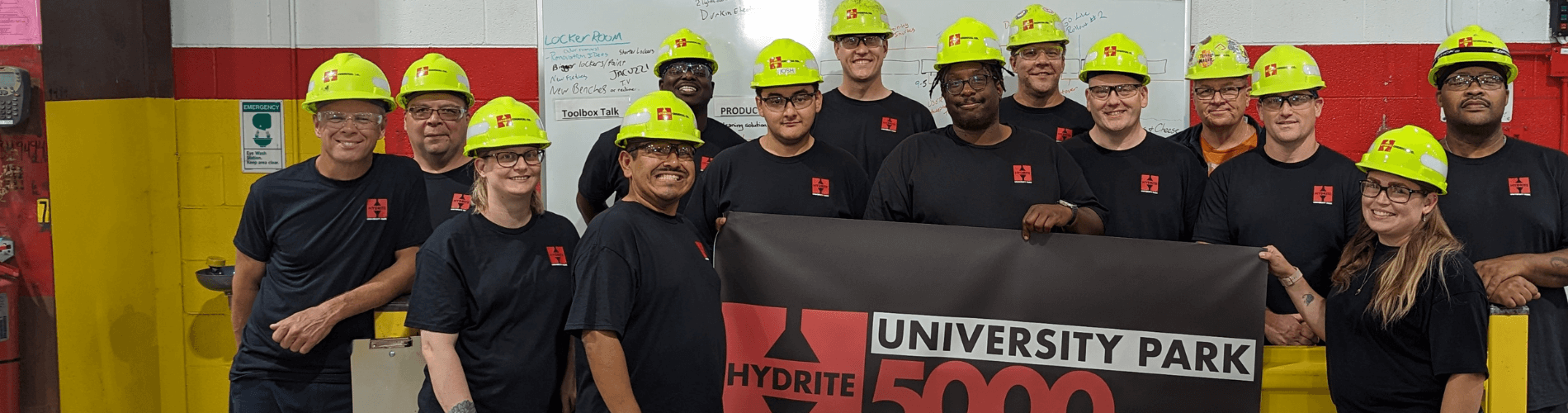

DRIVING ONE HYDRITE SAFETY

Our One Hydrite Safety team consists of a cross-functional group that includes Environmental, Health and Safety, Operations, Human Resources, Transportation, Risk Management, and Sales personnel to drive our One Hydrite Safety program to support our Safety Vision, Mission, and Values. This initiative requires identification and evaluation of the language, actions, and behaviors of individual employees, teams, and the culture we aspire to become and communicate this as the expectation.

These expectations are our safety leading indicators and are communicated, measured, acknowledged, and understood as the strategic path forward to deliver our vision, evaluate risks, implement prevention measures, and plan for current and future initiatives.

These practices and investment in a One Hydrite Safety culture has supported our achievement of record-breaking safety performances, driving our best year yet in 2022 and winning the 2023 Wisconsin Safety Council Corporate Safety Award.

"It is important that our employees be able to trust each other - they are not only responsible for their safety, but their teammates' safety as well."

Mike Smith

Branch Buyer / Warehouse Manager

La Crosse, Wisconsin

"Everyone should care about safety because when employees get injured, it also affects their loved ones at home."

Byron Chitay

EHS Specialist

Visalia, California

Customer Impact

Through an extensive quality management system, Hydrite is committed to providing high quality, creative products that exceed customer expectations. This commitment requires a strong understanding of our customer’s business, operations, and specifications. We are always working to further develop our equipment technology to meet the changing needs of customers. Our development of innovative tools for our customers and field employees, including real time data monitoring, demonstrates the company’s dedication to helping enhance food safety.

As a food sanitation and ingredient industry partner, we have spent decades promoting the safe transfer of food from farm to table. In the late 1990s, we implemented Hazard Analysis Critical Control Point (HACCP) plans in all manufacturing and warehousing facilities. HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, manufacturing, distribution, and consumption of the finished product. More recently, we have obtained Safe Quality Food (SQF) certification at a number of facilities.

Supplier Code of Conduct

A key piece of our success is our record of building strong relationships with our suppliers, who play an important role in our ability to live out our mission of providing sustainable ideas and solutions that ensure customer, employee, and partner success. We hold ourselves to exacting standards, and we expect the same from our suppliers.

Contact Us

Learn more about how Hydrite prioritizes safety company wide.