Fermentation Solutions

Innovative Chemistry, Proven Performance, and Complete Support for Every Fermentation Industry

Hydrite delivers complete fermentation chemistry and application expertise for biofuels, food & beverage, precision fermentation, and industrial bioprocessing. Our solutions improve yield, protect against contamination, support efficient CIP, and optimize performance across microbial systems.

What Is Hydrite’s Approach to Fermentation?

Hydrite’s approach blends advanced chemistry, technical expertise, and process support to help manufacturers run cleaner, safer, more efficient fermentation operations. We combine foam control, antimicrobials, nutrients, pH systems, sanitation, CIP, and water treatment into a unified support model.

Why Choose Hydrite?

Hydrite manufactures many of the chemistries including bisulfites, peracetic acid (PAA), ingredients, commodities, foam control, wastewater treatment and CIP chemistries required for fermentation, enabling unmatched supply reliability, product quality, technical accuracy, and industry‑specific problem solving. Our multi‑location local stocking, direct delivery network, food-grade manufacturing facilities, and in‑house expertise make us a trusted partner for producers across North America.

Fermentation Solutions Across Industries

Hydrite's expertise spans a wide variety of industries including fuel ethanol and biofuels, dairy and cultured products, beverages, brewing, precision fermentation, alternative proteins, organic acids, enzymes, bioprocessed ingredients, chemical and speciality industrial fermentation.

Biofuels & Ethanol Fermentation

Hydrite helps ethanol plants overcome common challenges such as inconsistent yeast activity, bacterial infections, lactic acid buildup, and antibiotic resistance. Our antimicrobial systems and case studies demonstrate measurable improvements in yield, sugar utilization, and fermentation stability.

Key Solutions

- Improved corn oil recovery

- Antimicrobial systems engineered to reduce lactic acid and target gram‑positive and gram‑negative bacteria

- pH control

- CIP and descaling chemistries for heat transfer and evaporator performance

- Foam control for mash, fermenters, and stillage systems

Food & Beverage Fermentation

What chemistry supports food‑grade fermentation?

Hydrite provides acids, pH control systems, preservatives, antimicrobials, and ingredients designed for dairy, cultured foods, beverages, pickled vegetables, and more.

Applications

- Dairy cultures (cheese, whey, yogurt)

- Vegetable fermentation (pickles, olives, kraut)

- Beverage fermentation

- Bakery preferments

Food‑Grade Solutions

- Citric, acetic, and lactic acids

- Potassium lactate blends

- Sorbates, benzoates, and phosphates

- pH‑adjustment systems for safe, consistent fermentation

- Foam control

Industrial & Chemical Fermentation

How does Hydrite support industrial fungal or bacterial fermentation?

Industrial fermentation demands control of foam, viscosity, oxygen transfer, and microbial contamination. Hydrite provides the full chemistry suite required to maintain healthy fermentation morphology and stable performance.

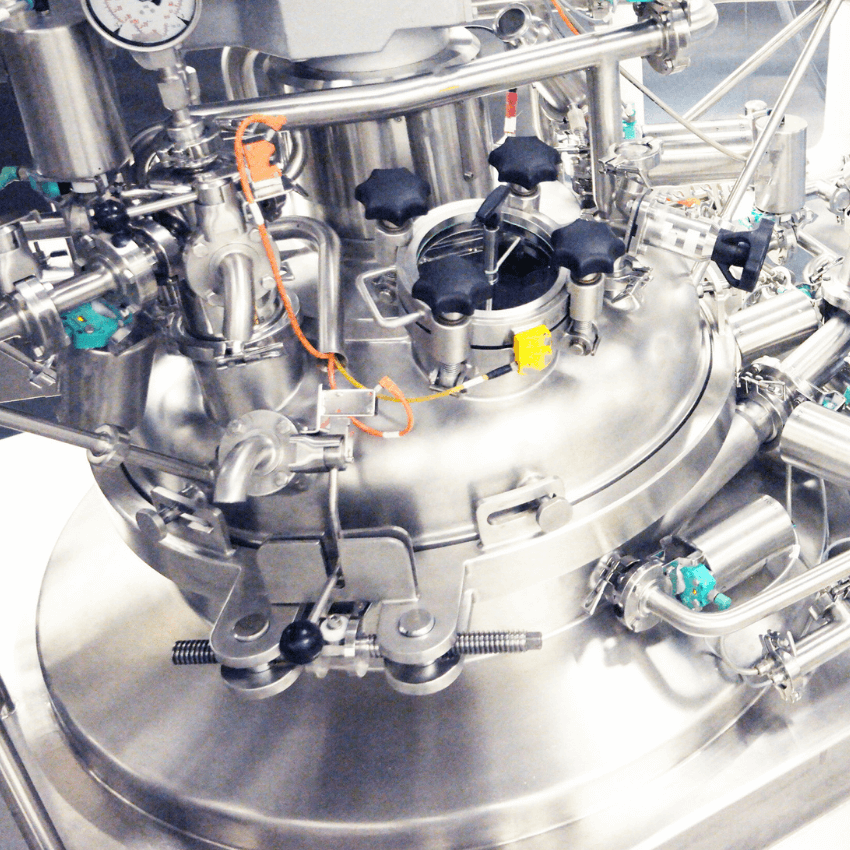

Precision Fermentation

Why is Hydrite relevant to precision fermentation?

Precision fermentation requires stable, sterile, foam‑controlled environments with dependable sanitation and water quality. Hydrite supports innovators across alternative proteins, enzymes, organic acids, specialty lipids, and bioprocessed ingredients.

Key Solutions

- Antifoams designed for aerated bioreactors

- CIP and sanitation chemistry for stainless and single‑use systems

- Food‑grade pH control agents

- Water treatment and boiler/cooling solutions

Teaming up to enable the path from early research to bioproduct commercialization.

The Integrated Bioprocessing Research Lab (IBRL) and Food Science Pilot Plant bridges advanced bioprocessing capabilities with complementary companies like Hydrite, creates a seamless pathway from innovation to scalable, industry-ready solutions. Our involvement in IBRL’s Fermentation Short Course reflects our shared commitment to elevating fermentation knowledge, innovation, and real‑world application across emerging and established bioprocess industries. Learn More

Fermentation FOAM CONTROL

The following Hydrite products are specifically designed to support and optimize foam control in fermentation processes across a range of applications.

- MCA 240: 100% active synthetic base formula ideal for wet corn milling, chemical processing, and sugar beet processing.

- MCA 250: 100% active synthetic base formula ideal for fermentation and chemical processing.

- Suppressor 3721: 100% active synthetic base formula ideal for sugar beet processing, yeast processing, and chemical processing.

- Suppressor 3531: Blend of natural and synthetic technologies ideal for plant-based proteins (pea, soy), fermentation (citric acid), and general food processing.

- Suppressor 3512: Silicone-free, 100% active formula ideal for fermentation with a low toxicity profile.

Comprehensive Support for the Entire Fermentation Lifecycle

What services does Hydrite provide for fermentation facilities?

On‑Site System Evaluations

Microbial & Water Analysis

Process Optimization & Troubleshooting

Scale Up & Application Engineering

CIP Program Optimization

Membrane Cleaning & Optimization

Custom Micro & Macro Nutrient Blending

Process Monitoring Solutions: SLM-RT & M3ASURE

Our expertise spans agriculture, food ingredients, foam control, biofuels, sanitizers, water treatment, and fermentation science.

Frequently Asked Questions (FAQs) About Fermentation

Foaming, contamination, microbial imbalance, low yield, pH instability, cleaning difficulties, water‑quality issues, and process inefficiencies.

Yes — Hydrite offers antimicrobial options and process aids that support antibiotic‑free production.

Absolutely. Our chemistry portfolio includes CIP solutions designed for proteins, biofilms, mineral deposits, and heat‑transfer improvements.

Yes. Hydrite supports everything from bench‑scale R&D through full commercial production.

Hydrite helps solve many common fermentation challenges including foaming, microbial contamination, inconsistent yields, slow fermentation rates, pH instability, lactic acid buildup, and cleaning inefficiencies within bioreactors and tanks. Our chemistry and technical support address both upstream and downstream issues for smoother, more predictable fermentation.

Hydrite provides antimicrobial options and process aids that help producers reduce or eliminate antibiotics in fermentation systems. This includes chemistry designed to target gram‑positive and gram‑negative bacteria without relying on conventional antibiotic pathways.

Yes. Hydrite’s foam control agents, antimicrobials, pH solutions, and CIP chemistries work in both aerobic systems (such as precision fermentation and industrial fungal processes) and anaerobic systems (such as ethanol production and certain food fermentations).

Hydrite supports fermentation across biofuels, food & beverage (dairy, pickled vegetables, cultured foods), precision fermentation, industrial enzymes, organic acids, alternative proteins, and chemical fermentation.

Absolutely. Our chemistry portfolio is engineered to stabilize microbial environments, reduce contamination risk, optimize nutrient availability, control pH, and improve aeration efficiency through proper foam management—all of which contribute to improved yield and batch repeatability.

Hydrite supplies food‑grade acids, pH control systems, preservatives, antimicrobial blends, and ingredients such as citric acid, lactic acid, potassium lactate, sorbates, and benzoates for dairy, beverage, and vegetable fermentation.

Yes. Hydrite offers complete CIP chemistry for removing proteins, biofilms, minerals, and microbial residues from fermenters, bioreactors, holding tanks, heat exchangers, and transfer lines.

Hydrite provides technical support, application expertise, lab analysis, and scale‑up guidance to help both emerging precision‑fermentation companies and established manufacturers accelerate development and troubleshoot process challenges.

Ready to Improve Your Fermentation Performance?

Hydrite helps producers improve yield, reduce contamination risk, stabilize fermentation conditions, and increase operational efficiency — across every fermentation market.