Food Ingredients & Processing Aids

At Hydrite, we go beyond chemicals—we deliver integrated solutions that empower food and beverage manufacturers to innovate with confidence. With over 40 years of experience, our multifunctional ingredient systems are engineered to enhance formulation accuracy, improve processing stability, and meet the highest standards of food safety. Whether you're optimizing dairy proteins for better melt and yield, enhancing beverage consistency with pH buffering and sweetener systems, or improving moisture retention in meat products, Hydrite provides the tools and expertise to help you scale efficiently and sustainably.

Our commitment to verified food safety, GMP-certified manufacturing, and on-site sanitation support ensures your operations stay ahead of evolving regulatory demands. From plant-based stabilizers to nutritional fortification blends, our diverse portfolio is tailored to meet your unique challenges—so you can focus on creating products that stand out in the market.

Work with Hydrite and experience the difference of a food ingredients provider that’s as committed to your success as you are.

The Hydrite advantage

Multifunctional Ingredients

Multifunctional ingredients tailored for customer needs

Dairy Protein Optimization

Dairy protein optimization for improved performance features & stability

Processing Efficiencies

Diverse liquid food ingredient systems to improve ease of use and consistency

Proven Food Safety

Proven food safety for improved quality

What makes Hydrite better?

We are a food partner with the capabilities to accelerate product innovation process efficiency & food safety.

-

Multifunctional ingredient systems that provide functional benefits & improvements in formulation accuracy and stability.

-

Decades of experience leading dairy and food processing with ingredients & efficiency tools.

-

Unique processing tools that increase efficiencies and scale production while reducing waste.

-

Food safety leadership in processing to meet the changing and improving food safety standards.

Beverages

- pH buffering technologies for taste stability

- Liquid citric acid systems tailored for product consistency

- Plant-based ingredients and stabilizers

- Liquid sweetener concentrates for ease in formulation

- Whey protein stabilizers for better processing

- Nutritional fortification blends

Meat

- Multifunctional ingredient blends for protein modification and improved moisture retention

- Liquid acidulant systems tailored by concentration

- pH buffering systems for optimizing processing

- Pathogen control with lactate blends

- Proven food safety sanitation programs

Dairy

- Technologies for modifying dairy proteins to improve melting characteristics & stability

- Optimizing whey protein yields in operations

- Nutritional fortification ingredients

- pH buffering to extend shelf life

- Proven food safety sanitation programs

PROVEN food safety

-

Industry-leading quality documentation & traceability

-

GMP manufacturing sites for multifunctional food ingredients

-

FSMA compliant and SQF certified

-

Dedicated onsite food sanitation resources with operational HACCP experience

-

Organic food sanitation programs

-

Portfolio of meat processing antimicrobials for pathogen control

Liquid Processing Aids

Processing aids help control unwanted scale formation and lead to longer and more efficient product runs. Our patented processing aids are the result of years of research and field testing to create the best product options for the dairy industry and beyond. These proprietary and/or patented blends of food-grade polyphosphates have been optimized for greater effectiveness over the use of single phosphate compositions. They have the potential for application anywhere undesirable calcium carbonate and calcium phosphate scale forms. They are proven to be effective in reducing fouling on contact surfaces in heat transfer equipment such as heat exchangers, pasteurizers, and evaporators.

- Lower ash in lactose

- Larger, more uniform crystals

- Uniform dehydrated properties

- Less caking

- Longer membrane life

- Lower processing pressures

- Facilitates whey protein stabilization

- Prevents formation of whey pudding and calcium fall-out

- Reduced solids fallout in concentrated permeate

- Less scale formation on evaporator and RO units

- Longer production runs

- More pounds per hour through evaporator

- Reduced energy usage

- Elimination of midday wash

- Fewer chemicals required for cleaning

- Greater product recovery/higher yields

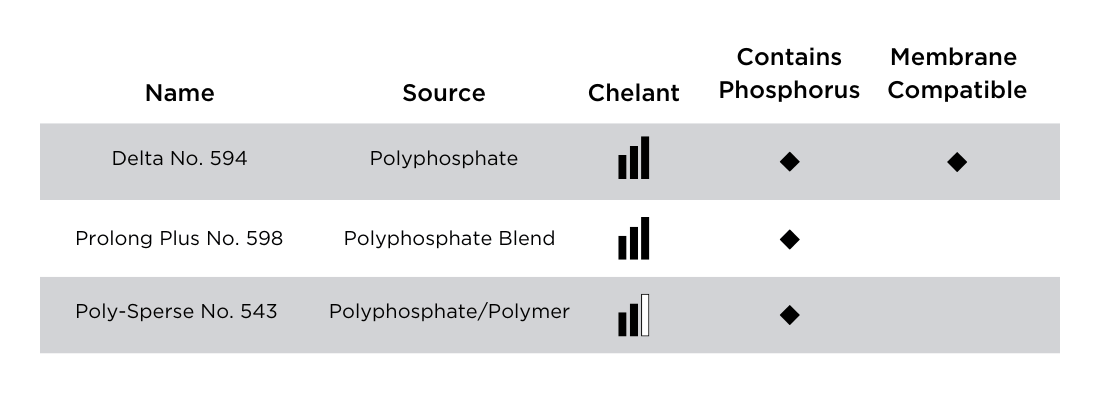

Products

Hydrite has a line of chelating processing aids that can be used in food processing equipment to prevent scale build up and reduced production throughput.

Delta No. 594 can be used in whey or lactose RO membrane systems to prevent mineral fouling.

Prolong Plus No. 598 is used in milk evaporators to reduce “white scorch particles” on sediment disk testing during production runs.

Poly-Sperse No. 543 is a high solids liquid chelating agent for use as a scale inhibitor during lactose processing.

Reverse Osmosis Membrane Systems

Delta No. 594 has been found to be extremely useful in controlling the fouling of reverse osmosis membrane systems. Scale build up equates to higher pressures, shorter production runs, higher energy costs and more time and chemicals required for cleaning which decreases membrane life. Additionally, our processing aids come in a liquid form that can be easily and accurately metered into the process stream through the use of a diaphragm pump. Learn more about our membrane technology solutions.

Contact Us

Connect with a Hydrite representative to learn more on how we do food ingredients better.