Reverse Osmosis Treatment

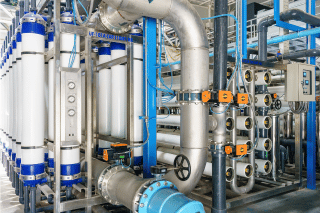

You rely on your Reverse Osmosis unit to deliver a consistent supply of high-quality permeate water for your processes needs. Hydrite understands the importance of proper RO feedwater pre-treatment to maximize recovery and reduce the frequency of downtime needed for membrane cleaning, allowing you to achieve longer production runs while extending the life of your membranes.

You rely on your Reverse Osmosis unit to deliver a consistent supply of high-quality permeate water for your processes needs. Hydrite understands the importance of proper RO feedwater pre-treatment to maximize recovery and reduce the frequency of downtime needed for membrane cleaning, allowing you to achieve longer production runs while extending the life of your membranes.

Antiscalants

Antiscalants are critical in managing feedwater contaminants and minerals of the RO membranes, allowing maximum recovery. Feedwater can vary in its constituents, which is why Hydrite carries a variety of antiscalants, including NSF options, that we can match to your specific needs. We utilize an advanced software program to select the proper antiscalant and dosage for the application while modeling flow to gain valuable insights and help operate your RO unit at peak efficiency while minimizing scaling potential and downtime.

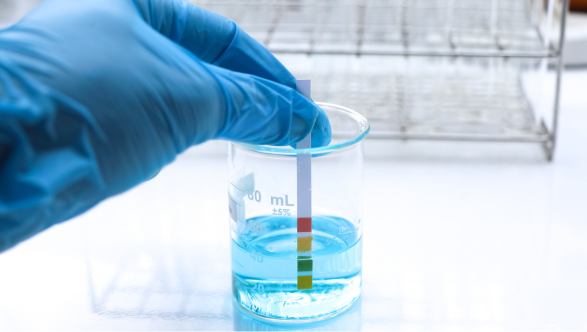

High and Low pH Cleaners

Hydrite carries both high and low pH membrane cleaners to remove organics, foulants, and mineral scales from your RO membranes to restore flux and peak performance. Our cleaners are compatible with thin-film composite and cellulose-acetate membranes.

Pre-Treatment Chemistries

Hydrite supplies chemistry for feedwater pH adjustment and dechlorination if your system requires it.

Our dechlorination products:

- Ammonium Bisulfite

- Neutral Bisulfite

- Potassium Bisulfite

- Sodium Bisulfite

Reverse Osmosis for Treating PFAS

Reverse osmosis can be a highly effective treatment for removing perfluoroalkyl and polyfluoroalkyl substances (PFAS) from water, including long-chain PFAS like perfluoro octanoic acid (PFOA) and perfluoro octane sulfonate (PFOS). These synthetic chemicals are often resistant to other traditional water treatment methods, making RO a comprehensive treatment option for contaminated water. Combined with other treatment methods like activated carbon or ion exchange, industrial wastewater and municipal water treatment facilities can meet or exceed EPA testing requirements.

Regular maintenance and pre-treatment chemistries are essential to keeping the system running smoothly and ensuring particulates and contaminants that can clog membranes aren’t introduced.

Contact Us

Connect with the water treatment team to learn more about industrial reverse osmosis.