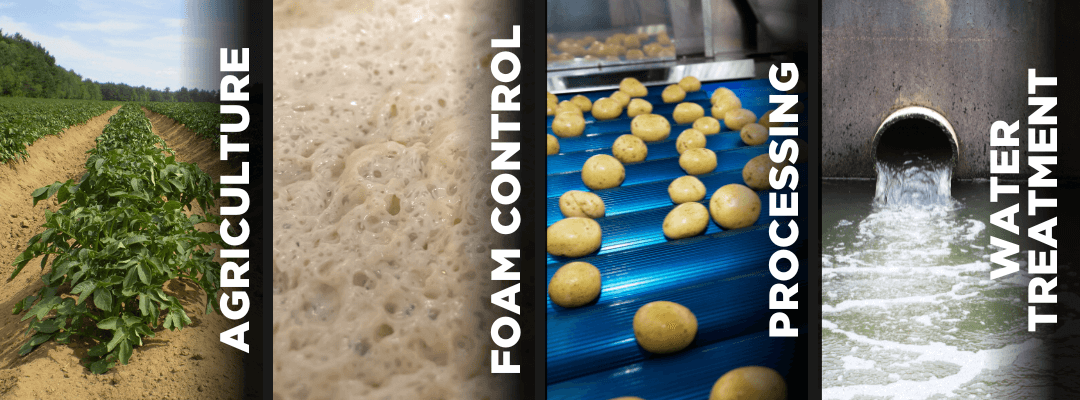

Potato Solutions

From Field to Facility

As one of the top vegetable crops in the United States, the potato industry requires sophisticated, efficient chemical solutions to ensure healthy crops, safe production, and sustainable processing. Hydrite offers chemical solutions for every step of the way. Whether it’s agriculture products on the field, processing aids in the facility, or wastewater treatment after production, our single-source approach keeps the big picture top of mind.

On the Field: Potato Ag Solutions

Hydrite's portfolio of innovative ag products and expertise in the field allows potato growers to maximize the efficiency and output of their growing season.

Applications

Fertilizers

Fertilizers

Fertilizers help potato growers improve the health of their crops, increasing crop yield.

What We Offer

- Ammonium Thiosulfate (ATS=™): A liquid fertilizer that provides both sulfur and nitrogen to potato crops, producing higher crop yields.

- Potassium Thiosulfate (Thio 25-17™): A liquid fertilizer that increases nitrogen utilization, improves drought resistance, and contributes to overall plant health.

- Low salt fertilizers: Fertilizers with a minimal salt index to prevent plant injury, stunted growth, and stress.

In the Facility: Potato Foam Control Solutions

During the transportation of potatoes through a flume water system, the potato’s proteins and starches can form stable foam. Other common foam-producing application points include washing, peeling, and cutting. To prevent and eliminate foam, Hydrite offers a full product line of control agents specifically designed for numerous FDA applications. Read the flyer +

Applications

General & Food-Grade Processing Aids

General & Food-Grade Processing Aids

Aids help prevent foam from flooding the operational floor, supporting increased throughput and product quality.

What We Offer

- Defoamers & Antifoams: Hydrite defoamers and antifoams deliver excellent performance throughout the manufacturing process, assisting in starch recovery while combating foam in washing and blanching.

- Silicone Emulsions: Like defoamers, silicone emulsions knock down foam generated from potato proteins and starches during processing. They are also helpful during potato wastewater treatment.

In the Facility: Potato Processing Solutions

Like any other vegetable, potatoes require thorough cleaning to keep harmful bacteria and pathogens out of the food supply. Whether they’re sold whole or used in the production of a potato-based product, Hydrite offers processing solutions to keep microorganisms at bay. Read the flyer +

Applications

Potato Washing

Potato Washing

Help control spoilage or decay-causing bacteria and fungi in water or ice that contact raw unprocessed potatoes.

Cleaning, Sanitizing & Disinfecting

Cleaning, Sanitizing & Disinfecting

Cleaning of potato storage areas, equipment, and other surfaces.

Wash Water Treatment

Wash Water Treatment

Treating water used in the processing of potatoes.

What We Offer

- Peracetic Acid: This powerful disinfectant has high oxidizing potential, making it effective against a broad range of microorganisms and its favorable environmental profile.

In the Facility: Potato Water Treatment Solutions

Water treatment is an important function in a potato processing facility, requiring the removal of settleable and dissolved solids to meet water quality standards. Hydrite’s water treatment team is experienced in developing solutions that meet the unique needs of this industry.

Applications

Liquid/Solid Separation

Liquid/Solid Separation

Settleable and dissolved solids are present in water used throughout potato processing, particularly during washing. Liquid/solid separation is required to meet water quality standards.

Odor Control

Odor Control

During potato processing malodors can occur, particularly during water treatment due to sludge generated during water clarification.

pH Control

pH Control

pH is an important attribute that impacts how water can be treated and disposed of. Adjustments to pH are commonly needed throughout the potato handling process.

Heating & Cooling

Heating & Cooling

Water treatment chemistries prevent scaling, corrosion, fouling, and other contaminant-related issues from impacting the performance of a potato processor's boiler and cooling, reverse osmosis, and closed loop systems.

What We Offer

- Caustic Soda: Used in pH control, caustic soda helps potato processors with low acidity to raise their pH. This chemical works hand in hand with sulfuric acid.

- Sulfuric Acid: Used in pH control, sulfuric acid helps potato processors with high acidity to lower their pH. This chemical works hand in hand with caustic soda.

- Coagulants: Used as a clarification aid in potato wastewater to remove contaminants.

- Flocculants: Used in liquid/solid separation to remove biological oxygen demand (BOD) and solids from potato wastewater, as well as dewater sludge.

- Odor Neutralizers: Controls malodor (unpleasant smells) in potato wastewater treatment.

Why Hydrite?

Hydrite’s strength lies in the technical capacity of our people and the experience they bring to our organization. With dedicated teams for each phase of a potato’s lifecycle, we have the expertise to provide full-circle, sustainable solutions no matter the application.

As a national supplier, our extensive network of manufacturing facilities, warehouses, and laboratories are supported by a private transportation fleet, meaning we’re able to get the products you need, when you need them.

Contact Us

Get in touch with a Hydrite representative to learn more about our potato agriculture and processing solutions.