Biofuels and Peracetic Acid

As the ethanol industry moves away from antibiotic antimicrobial treatments, new options like peracetic acid (PAA) have emerged as a popular and potent alternative. Hydrite has developed PAA chemistries like EPA-registered Hydritreat that are specifically designed for ethanol applications. In addition to performance improvements, PAA promotes sustainability with no toxic byproducts and safe decomposition.

How is Peracetic Acid (PAA) Used in Ethanol Production?

PAA is an excellent antimicrobial agent due to the chemistry’s high oxidizing potential, the effectiveness against a broad range of microorganisms in cold and warm temperatures, and the favorable environmental profile. Produced in the Midwest, Hydrite’s peracetic acid offers a host of operational benefits:

Antimicrobial for bacteria control in fermenters, mash coolers, and scrubbers

Sulfite oxidation to reduce sulfur content in ethanol

Oxalate, protein, and scale removal for clean in place (CIP)

Environmentally safe slime-forming bacteria control and removal in cooling towers

Case Studies: The Power of PAA in Ethanol Production

Hydrite has conducted extensive trials for peracetic acid applications within the biofuels and ethanol industry. An excellent antibiotic-free alternative to traditional antibiotic treatments, PAA has proven to be a high-performing and cost-effective option with no known bacterial resistance. Read the case studies below to better understand the power of PAA.

Slime-Forming Bacteria Reduction in Cooling Towers

Before adding Hydrite’s EPA-registered Hydroxycide 1522, slime-forming bacteria levels were high resulting in poor heat transfer and frequent cooling tower packing (fill) replacements. After adding peracetic acid to cooling towers, producers recorded:

- A reduction in packing fouling (slime-forming bacteria)

- Improvements in heat transfer and process control

- Reductions in treatment and energy costs

Lactobacillus Reduction in Ethanol Fermentation

An ethanol plant implemented Hydritreat SB1523 to help reduce antibiotic usage, reduce costs, and improve performance. The change reduced treatment costs by more than $150,000 with improved ethanol fermentation performance.

Bulk PAA For Biofuels

Hydrite is proud to provide PAA in bulk for the biofuels industry. Bulk PAA can be a safe, economical option for a wide range of applications. Delivered by Hydrite's private, state-of-the-art transportation fleet, manufacturers can benefit from PAA's powerful + versatile profile, while staying financially conscience.

Peracetic Acid Antimicrobial Control

One of the most important processes in fuel ethanol production is yeast fermentation of glucose into ethanol. When fermentation is running well, downstream operations run well. If fermentation does not run well, downstream processes become fouled and low-quality byproducts are produced. Fuel ethanol output is also compromised, reducing facility profits.

Bacterial infections are one of the biggest contributing factors to poor fermentation. Infections inhibit yeast’s ability to ferment sugar into ethanol. Ethanol facilities can spend hundreds of thousands of dollars annually on antibiotic use to stop the spread of infection. Often antibiotics are overdosed to ensure overall bacterial control but also allowing bacterial strains to gain possible resistance to the antibiotics. Furthermore, traditional antibiotics are only effective against gram-positive bacteria (lactobacillus) and not gram-negative bacteria (acetobacter and pseudomonas). Gram-negative bacteria consume valuable sugar and contribute to poor fermentation.

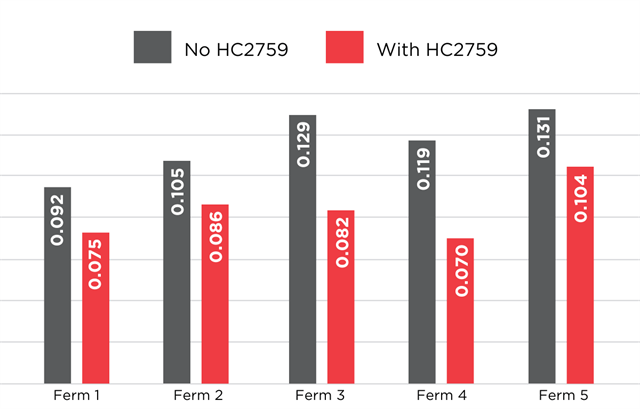

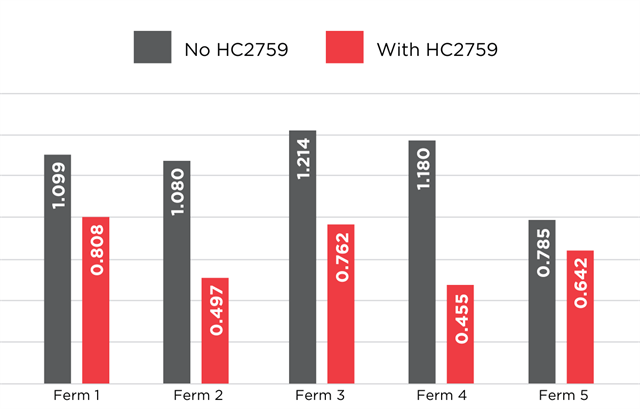

Hydrite’s proprietary Hydrimaize 2759 decreased antibiotic usage by >60%, decreased acetic acid content by 28%, and decreased lactic acid content by 41%, with an overall 40% decrease in antimicrobial costs.

ACETIC ACID CONTENT AT DROP

LACTIC ACID CONTENT AT DROP

Is PAA Right for Your Ethanol Plant?

Get in touch with the biofuels team to see how peracetic acid can improve your plant's performance.