Odor Control and Peracetic Acid

Known for its antimicrobial properties, peracetic acid (PAA) is widely used for sanitation and odor control. As a heavy, stable liquid that is very soluble in water, PAA is many times more effective than conventional oxidizers like bleach, peroxide, and chlorine dioxide. Additionally, its byproducts do not become food sources for bacteria. This makes PAA an ideal choice for manufacturers and processors to reduce or eliminate unwanted odors.

What Industries Use Peracetic Acid for Odor Control?

Animal Processing

Animal processing and rendering facilities produce sulfur and nitrogen-containing compounds causing foul smells.

Biofuels

Factors like organic material breakdown, sulfur compounds, and processing methods can cause unwanted odors.

Water Treatment

Water systems in a variety of industries can be impacted by hydrogen sulfide and other odor-causing compounds.

Benefits of Peracetic Acid for Odor Control

Microbes cost industries billions of dollars per year in compromised product. Optimizing a facility’s antimicrobial program with PAA not only improves sanitation, but controls emissions and unwanted odors with a host of added benefits.

- Improved Performance: PAA is more effective than conventional oxidizers like bleach, chlorine dioxide, and hydrogen peroxide, and won’t be deactivated by organics in scrubber water.

- Enhanced Safety: By using peracetic acid, operators are not exposed to chlorine dioxide fumes at the rendering plant, creating a safer working environment.

- Cost-Effective: Peracetic acid performs multiple functions during chlorine dioxide generations that would normally require multiple chemicals:

- The acid chews up mineral deposits and scale

- Its oxidation mechanisms penetrate organic scale

This approach to odor control minimizes equipment (generator) maintenance and creates opportunities for cost savings with single-chemical bulk purchasing.

- Easy to Use: Most chlorine dioxide generators use a Venturi system that can be safely used to feed peracetic acid, eliminating the need for new pumps and equipment. Additionally, operators are only tasked with monitoring one chemical vs. multiple chemicals, simplifying operations.

Treatable Odor Compounds

Peracetic acid reduces odor at the scrubber system, the plant facility, and the surrounding community. It’s effective against a range of treatable odor compounds including:

- Hydrosulfide: (hydrogen sulfi de liquid phase)

- Thiols (mercaptans): (methane-, ethane-, etc.)

- Volatile fatty acids: (butyric, acetic acid, etc.)

- Carbon disulfide

- Dimethyl sulfide (-disulfide, -trisulfide)

Case Study: Odor Control in Animal Processing Facilities

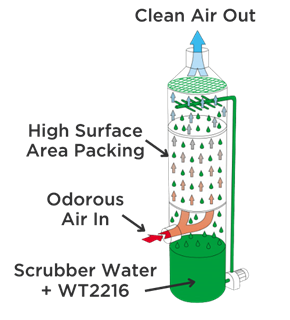

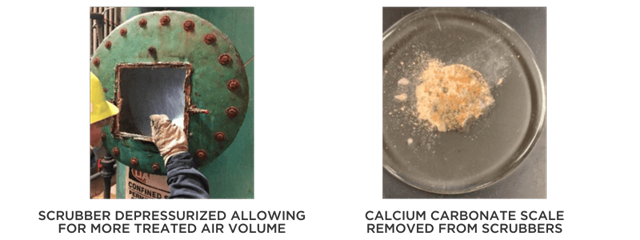

Animal processing facilities use chlorine dioxide gas to reduce odor. Chlorine dioxide gas is generated on site using multiple chemicals and introduced into a hard water stream that feeds a packed scrubber. The scrubber then removes odors in the incoming air to emit “odor-free” clean air into the atmosphere. Challenges during this process included poor performance, scale buildup, expensive chemicals costs, and complex equipment maintenance. After implementing PAA product Hydritreat WT2216, a processing facility:

Animal processing facilities use chlorine dioxide gas to reduce odor. Chlorine dioxide gas is generated on site using multiple chemicals and introduced into a hard water stream that feeds a packed scrubber. The scrubber then removes odors in the incoming air to emit “odor-free” clean air into the atmosphere. Challenges during this process included poor performance, scale buildup, expensive chemicals costs, and complex equipment maintenance. After implementing PAA product Hydritreat WT2216, a processing facility:

- Reduced odor complaints by >85% in the surrounding community

- Lowered treatment costs by >30% + eliminated caustic CIP

- Reduced required generation equipment to just 1/3, simplifying equipment maintenance

- Improved employee safety by eliminating chlorine dioxide

Bulk PAA For Odor Control

Hydrite is proud to provide PAA in bulk for odor control applications. Bulk PAA can be a safe, economical option for a wide range of applications. Delivered by Hydrite's private, state-of-the-art transportation fleet, manufacturers can benefit from PAA's powerful + versatile profile, while staying financially conscience.

Peracetic Acid Products for Odor Control

A leader in PAA, Hydrite offers a range of peracetic acid products designed to tackle odors in industrial and food applications:

Hydritreat WT 2216

Hydritreat™ WT 2216 is an aqueous mixture of peroxyacetic acid (PAA) and hydrogen peroxide used as a liquid antibiotic free antimicrobial. It can be directly injected into fermenters, dead legs, mash coolers, CO2 scrubbers, and similar applications to provide odor control and H2S oxidation.

Hydritreat SB 1523

Hydritreat™ SB 1523 is an aqueous mixture of peroxyacetic acid (PAA) and hydrogen peroxide for odor control in animal rendering processes.

Hydri-Maize 2759

Hydri-Maize™ 2759 is an aqueous mixture of peroxyacetic acid (PAA) and hydrogen peroxide that can be used for odor control in rendering processes. Also GRAS for use in descaling agent in CIP tanks, as an antimicrobial agent in the fermenter in ethanol processing, and as an antimicrobial agent in pressed cake in rendering.

Control Odor with PAA

Keep odors out of your facility, your community, and the environment with PAA.