Single Phase Cleaning – Enhance 567

Do you have concerns about cleaning time, acid usage, water usage, and energy consumption?

Enhance No. 567 is a concentrated chelant additive that “enhances” the cleaning effectiveness of caustic solutions, especially in hard water. It also helps control excessive foam formation and aids in rinsing. When used at elevated concentrations, in the range of 3400 to 6600 ppm chelation, it can dissolve mineral scale from equipment surfaces— reducing or eliminating the need for an acid wash and associated rinse.

Product Features

- Non-phosphated to reduce effluent phosphorous levels.

- Contains powerful chelating agents that can dissolve and disperse calcium and magnesium deposits.

- Can be added to caustic cleaning solutions to boost detergency and aid in washing and rinsing in hard water.

- Can reduce and/or eliminate the need for acid washes when used at recommended concentrations.

Applications

- For evaporator, separator, and HTST cleaning, add 1.0 to 1.5 ounces of Enhance No. 567 per gallon of caustic cleaning solution.

- For moderately hot processing equipment, add 0.5 to 1.0 ounces of Enhance No. 567 per gallon of caustic cleaning solution.

- Enhance No. 567 should be added to cleaning solution prior to heating the water and BEFORE significant foam is present.

- This product can be used at higher usage levels than listed for heavy soil loads, burnt on soils, or other conditions where more chemical is required to remove the soil.

- Enhance No. 567 should not be used to clean heavy mineral deposits such as those found in a lactose permeate evaporator—CIP acid is better suited for this application.

Case study

Below are pictures of a skim milk evaporator tube chest after a single-phase wash was completed with Enhance 567 over a 7-day trial.

- CIP Time saved: 1 hour and 20 minutes.

- Water saved: 1 million gallons/year.

Top of skim milk evaporator tube chest Bottom of skim milk evaporator tube chest

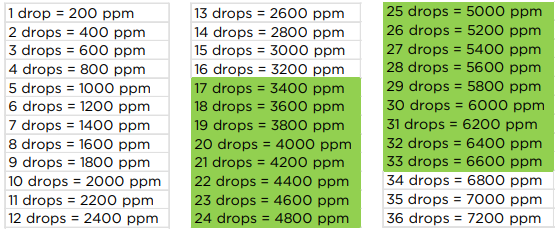

Also included is a titration procedure cheat sheet showing the 0.7 to 2.0 oz/gal range in ppm.

0.7 oz/gal = 3400 ppm 1.0 oz/gal = 4800 ppm 1.5 oz/gal = 5700 ppm 2.0 oz/gal = 6600 ppm

Enhance No. 567

- Draw a sample for testing and place in a secondary container or vial.

- Using a syringe, draw a 2.5 ml sample from the secondary container and transfer it to a clean titration vial.

- Add 1 scoop of Methylthymol Blue Indictor (0036) and mix.

- Add 6 drops of pH Buffer (0037) and mix. The sample should turn yellow.

- Titrate with 0.04M Bismuth Nitrate (0038), counting the drops until the sample turns blue/purple.

Calculation: Each drop = 200 ppm total chelant

Reach out to The RITE Team® for more information on single phase cleaning.