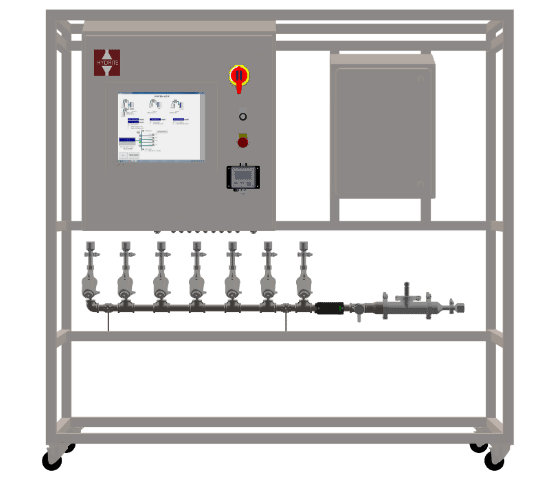

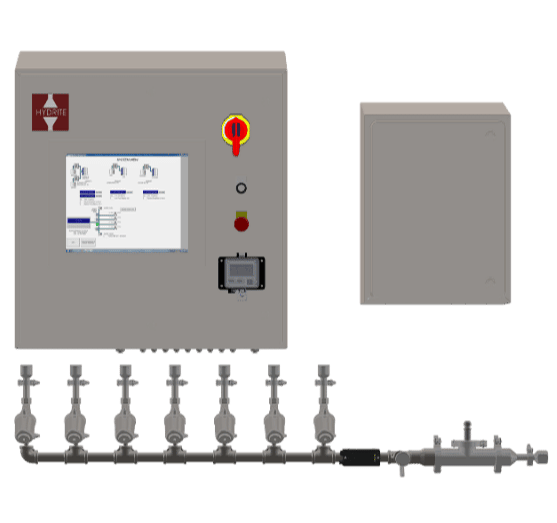

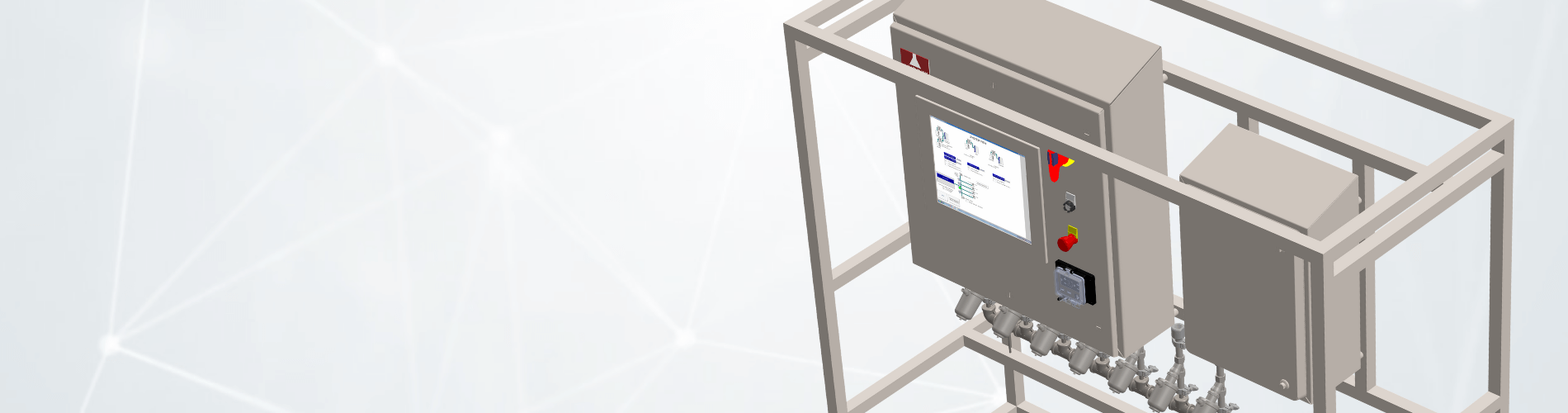

Hydri-Vision RT™

Next Gen Hydri-Vision

Can chemical or sanitizer concentration legitimately be measured in real time?

In many facilities, cleaning processes still rely on manual monitoring, visual inspections, and assumptions about chemical concentrations. That leads to variability, inefficiency, and uncertainty. Hydri-Vision RT replaces guesswork with science so you can clean with confidence and optimize every cycle.

evolution of Hydri-vision

Continuous improvement and evolution of the Hydri-Vision equipment line provides a best-fit option for every facility.

Hydri-Vision™: Technology for collecting, analyzing and documenting concentrations of cleaning, sanitation and intervention chemistries. Food safety, verification and validation as well as quality of an applicable finished product are foundational to this creative solution.

Hydri-Vision DLX™: An enhanced model of the Hydri-Vision, the Hydri-Vision DLX includes the ability to measure and record pH and titrations automatically, making it a second set of eyes to support food safety and sanitation programs.

Hydri-Vision RT™: The newest addition of the Hydri-Vision line, it utilizes real-time technology for analyzing your chemical and sanitizer concentrations within your current CIP program to provide insight into procedural changes for reduction in time, chemistry, energy, or water. By knowing specific concentrations for each product utilized in an individually cleaned circuit, recommendations can be made for optimizing the current program or investigating the impact of program changes while minimizing risks to production schedules, processing equipment components and food safety.

Why is Chemical and Sanitizer Concentration Monitoring Important?

Monitoring offers potential for increased profits, reinforced sustainability initiatives, enhanced food safety programs, and improved finished product quality.

Clean-In-Place (CIP) Innovation

In most clean-in-place or stand-alone systems, a point of reference is utilized for determining the method to control chemical or sanitizer concentrations on an individual cleaning circuit. As chemistry is added and temperature increases, said concentrations can and will change (or be impacted). During the wash and/or near completion, chemical or sanitizer concentrations will be diminished to minimal or no efficacy. In these moments, the control method may not appropriately recognize this loss in efficacy and soil may redeposit. When the changes in chemical or sanitizer concentrations are monitored throughout a CIP program, this information can be analyzed for optimization opportunities.

How Does Hydri-vision rt™ work?

An in-depth analysis of CIP samples is used to determine how chemical or sanitizer concentrations evolve or change throughout any given CIP circuit, including rinse applications. This can ultimately result in building a new CIP program with fewer redundancies or wasted resources.

Hydri-Vision RT™ can be built and analyze for:

- Impact on chemical or sanitizer concentrations during cleaning cycle heat-up times

- Stretches of a wash where chemical or sanitizer concentrations are no longer in specification

- Fluctuations or variability in pH of CIP solution

Insights gained can support decisions around:

- Time reduction

- Effects of changing chemistries

- Whether water usage can be reduced or eliminated through alignment to an applicable cleaning cycle (without significantly impacting a wash)

hydri-vision RT™ benefits

- Smart, Automated Cleaning Validation: Continuously monitors each cleaning step to detect when surfaces are truly clean, then automatically advances the process and confirms proper chemical and sanitizer concentrations.

- Hands-Free Operation: Fully automated interface minimizes or eliminates the need for manual intervention.

- Consistent, Reliable Results: Reduces day-to-day variability in cleaning processes, ensuring dependable performance.

- Science-Backed Confidence: Verifies food contact surface cleanliness without relying on visual inspection.

- Boosted Productivity: Speeds up cleaning cycles, freeing up more time for production and potentially lowering water and energy usage.

- Reagent-Free Sensor Technology: Advanced sensors operate without the need for chemical reagents.

- Built-In Data Intelligence: PC-based system captures, visualizes, and interprets data internally for actionable insights.

- Real-Time, Continuous Sampling: Constant monitoring ensures immediate feedback and control.

Analyze the Process

Continuous Sampling & Testing

Data Visualization

Compile Benefits and Establish an Action Plan

Contact Us

Connect with a Hydrite representative to learn more on why Hydri-Vision RT™ is right for your process.