Environmental Sanitary Design

Much attention is given to the sanitary design of food contact surfaces. Sanitary design standards for food processing equipment are written by the 3-A Sanitary Standards Organization. The comprehensive list of standards can be found at https://www.3-a.org/standards. For equipment sourced from the EU, sanitary standards that are written by the European Hygienic Engineering Design Group (EHEDG). The EHEDG standards can be found at https://www.ehedg.org. Equipment sourced from the EU, but used in the US, should conform to 3-A standards as well.

Often overlooked is the need for sanitary design to extend to non-product contact surfaces, equipment support structures, ancillary fixtures, and the general processing environment. Poor sanitary design in these areas can lead to hard-to-find/hard-to-clean harborage areas and growth niches for spoilage organisms and pathogenic bacteria. The daily sanitation practices of rinsing and washing can flush microorganisms from their harborage location to the open plant, where they can be spread to other areas of the plant via employee and equipment traffic – potentially being transferred to product contact surfaces and adulterating food.

Proper consideration must be given to every component and structure in the food manufacturing environment to prevent the creation of harborage areas and growth niches. In addition, periodic and thorough review of the plant environment must be conducted and systems properly maintained—even the best sanitary design will experience wear and failure. Cracks WILL eventually develop in floors and walls.

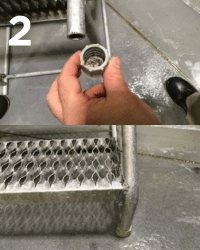

Below are photos highlighting common design flaws that can lead to plant micro issues:

1: Cracked epoxy-coated floor

2: Hollow tubes not properly welded/capped

3: COP Tank – Flush-mounted to wall – impossible to clean behind

Reach out to The RITE Team® for more information on environmental sanitary design.