Boiler Water Treatment

Boiler System Management

Hydrite recognizes that an efficient and reliable steam system is critical to your operations. Hydrite takes care in assessing your unique system to prescribe the proper chemical program and application to maximize asset protection, prevent unplanned downtime and lost production, and minimize operating costs. Hydrite has designed programs that are approved for use in any industry, be it food or dairy processing, brew and beverage, general manufacturing, and anything in between. Your Hydrite representative will work closely with your team as a partner and provide support each step of the way to ensure optimal program performance while continually searching for opportunities to conserve resources, improve efficiency, and drive down operating costs.

Hydrite recognizes that an efficient and reliable steam system is critical to your operations. Hydrite takes care in assessing your unique system to prescribe the proper chemical program and application to maximize asset protection, prevent unplanned downtime and lost production, and minimize operating costs. Hydrite has designed programs that are approved for use in any industry, be it food or dairy processing, brew and beverage, general manufacturing, and anything in between. Your Hydrite representative will work closely with your team as a partner and provide support each step of the way to ensure optimal program performance while continually searching for opportunities to conserve resources, improve efficiency, and drive down operating costs.

How Can Hydrite Help Your Boiler System?

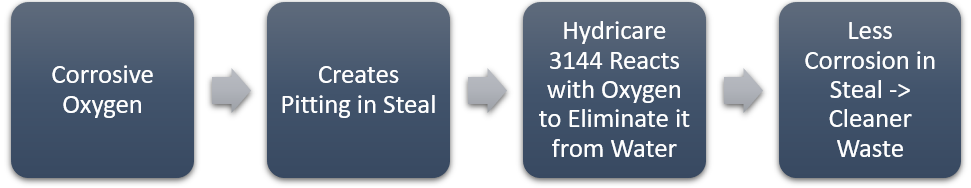

Oxygen Scavengers

Oxygen corrosion and attack can cause swift and severe damage in a boiler system, resulting in equipment failure, unplanned downtime, and significant costs in lost production and equipment repair. To manage this problem, Hydrite carries a line of uncatalyzed and catalyzed oxygen scavengers to address a range of applications to maximize chemical use efficiency and asset protection. Our product Hydricare 3144 helps with oxygen corrosion that can create pitting in the steel of your systems. This product reacts with O2 and aerates the system. Your Hydrite Representative will assess your system to determine proper product selection and application to ensure optimal results.

Internal Treatment

Scale and deposition in a boiler quickly robs heat transfer efficiency, resulting in increased fuel costs while increasing the potential for damaging under deposit corrosion and boiler tube overheating and failure. To combat this, Hydrite has developed Hydricare 3121, a high-performing internal treatment program designed to manage contaminants and hardness upsets to maintain maximum heat transfer efficiency and performance. This product is mainly applied for scale corrosion resistance. Hydrite’s specialized blends allow you to maximize cycles of concentration in your boiler, minimizing water, energy, and chemical usage. Your Hydrite Representative will assess your system to determine proper program selection and application to maximize system efficiency.

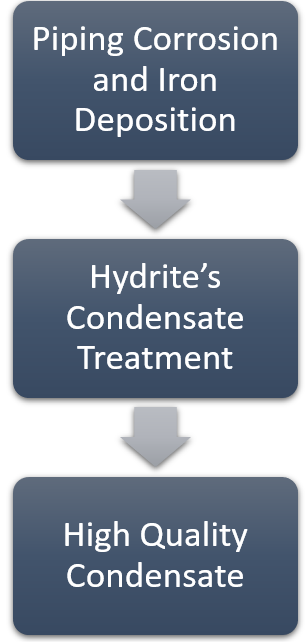

Condensate Treatment

Returning high quality condensate is extremely valuable to a boiler system, reducing water and energy usage. However, corrosion in the condensate system can have negative consequences that affect not just the condensate piping but that stretch all the way back to the boiler. Corrosion of condensate piping can result in the need for frequent and inconvenient piping replacements, costing you time and money and lost condensate. Dissolved Iron in the condensate due to this corrosion travels back to the boiler feedwater and ultimately the boiler, resulting in unwanted deposition. To prevent this damaging condensate system corrosion, Hydrite is able to employ a range of treatments, specifically Hydricare 3153, aimed at neutralizing the acidic condensate or producing a protective film on the condensate piping. With a range of treatment options to address any industry and systems of varying size and complexity, you can rest assured that your condensate system is protected while returning high quality condensate back to your boiler system, helping to maintain peak operating efficiency.

Digital Technology & Equipment: Ackumen

Boiler operators are constantly battling issues that plague their boiler system processes. Scaling and corrosion. Pretreatment and boiler inefficiencies. High fuel, chemical, and repair costs. Decreased equipment life. And unscheduled downtime. But did you know that you can predict and minimize those problems? At every stage—from pretreatment to boiler to condensate?

Pretreatment

Water Softener

If it’s not working right, you’ll learn why and what you need to adjust it. You’ll address the potential for a scale problem before it makes it to the boiler, and reduce the likelihood of heat transfer inefficiency and avoidable stress on boiler equipment

Softener Regeneration

You’ll get feedback on every softener regeneration to increase the likelihood your system is brining correctly. Contrast that with the manual alternative, an elution study, usually done once or twice a year. By ensuring regeneration is good, you’ll reduce the risk of scaling before it becomes an issue and potentially prevent unnecessary damage to your equipment.

Deaerator Operation

You’ll make sure your system is optimally and effectively removing residual oxygen. You’ll reduce boiler corrosion, increase system efficiency, and decrease the risk of system failure. And you can’t get this service from anybody else in the industry

Boiler

Stack Gas Temperature

You’ll understand if you’re burning fuel efficiently. And if not, you can make adjustments and reduce the potential for scaling that leads to boiler inefficiencies. You’ll also get 24/7 monitoring which increases the certainty that the right chemistry is being used when boilers are idle or offline.

Enhanced Boiler Control

You’ll be able to control boiler water chemistry 24/7/365, including integrating blowdown control, using advanced technology, trained water treaters and state-of-the-art digital platform.

Condensate

Corrosion in the Condensate

You’ll reduce corrosion that results from condensate that’s too acidic. You’ll protect pipes, and reduce energy inefficiencies and excessive feedwater usage.

Want to learn more about Hydrite's creative solutions for treating boiler systems?

Contact Us

To learn more about Hydrites products and solutions that help boiler system management, contact a rep today.