Corn Oil Optimization

Corn oil is an important co-product that plays a significant role in the profitability of fuel ethanol facilities. Hydrite offers next-generation chemistries and the Hydri-Maize Index percent oil analysis to empower ethanol facilities with the insights and tools needed to optimize their corn oil extraction process.

Next Generation Chemistry

Hydrite focuses on developing new products that help our customers improve their operations and enhance their total system performance. This includes new GRAS formulations for corn oil extraction, CIP, bacteria control, and VOC abatement. Our chemists work to develop new and improved products that offer the latest technology to address a wide range of operating system conditions.

Fermentation

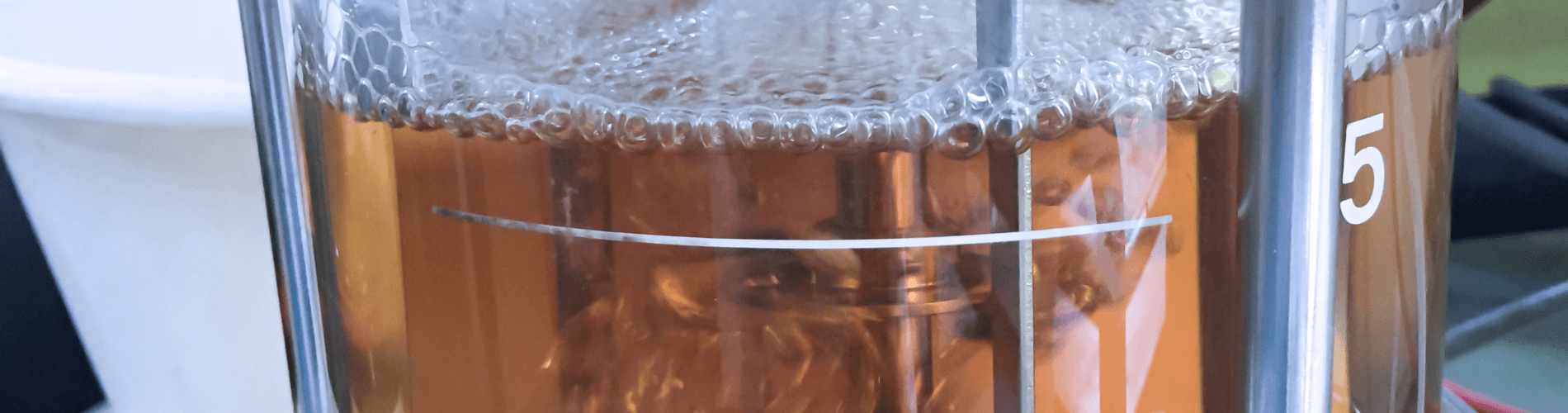

In corn oil production, fermentation involves converting corn starch into ethanol using microorganisms like yeast. This process breaks down the starches into sugars, which are then fermented to produce ethanol, a key step before extracting the oil. Hydri-Maize demulsifiers exhibit exceptional heat tolerance, shear tolerance, and dispersion properties, enabling effective deployment post-distillation to maximize oil recovery.

Hydri-Maize Helps:

Increase Recovery Rates: Hydrite demulsifiers are specially engineered to handle changes in syrup chemistry caused by fermentation enzymes, supporting over 99% recovery of corn oil at COE centrifuges.

Eliminate Foam: Fermentation defoaming enzymes can strip free fatty acids from corn oil, reducing production, quality, and trapping oil in emulsions. Hydrite's non-enzyme, FISMA-compliant defoamers effectively eliminate foam, boost production, and mitigate these challenges.

Hydrite further enhances production efficiency by leveraging its Hydrimaize Index mass balance technology alongside these demulsifiers.

Evaporation

In corn oil production, evaporation involves removing water from the ethanol mixture obtained after fermentation. This step concentrates the ethanol, making it easier to separate and purify the corn oil during subsequent processing stages. By addressing key challenges through chemistry and process changes, significant improvements can be achieved in both operational performance and product quality.

Hydri-Maize Helps:

Reduce Downtime: CIP-related evaporator downtime can extend to 12 hours, resulting in over 500,000 pounds of annual corn oil loss. Hydri-Maize 2759 and Hydrite’s advanced CIP procedure reduce downtime to under 3 hours, enhancing oil recovery while eliminating the need for hydro-blasting in evaporators.

Safeguard Quality: Leaking seal pots introduce transition metals into evaporators, which, catalyzed by heat and water, strip free fatty acids and decrease corn oil production. Hydrite’s Hydri-Maize Scale Control 200 binds transition metals, safeguarding corn oil quality and increasing recovery rates.

Delta T Plants

Optimizing corn oil extraction in ethanol production enhances the value of dry distiller's grains (DDGs) by increasing their oil content and improving their marketability as livestock feed. Hydrite demulsifiers can support maximizing Delta T distillers’ corn oil recovery by providing optimal surfactancy, precision temperature control, and effective dosing, all while producing bright, high-quality dry distiller’s grains (DDGs).

Hydri-Maize Helps:

Preserve DDG Color Quality: Hydri-Maize CB-400 complements Hydrite demulsifiers by allowing Delta T plants to raise syrup retention tank temperatures above 200°F without compromising DDG color. By halting the Maillard reaction, Hydri-Maize CB-400 ensures bright, high-quality DDG while enhancing oil recovery.

Together, Hydrite demulsifiers and Hydri-Maize CB-400 enable Delta T plants to achieve peak oil recovery and maintain superior product quality.

Percent Oil Analysis

Corn oil is an important co-product that plays a significant role in the profitability of fuel ethanol facilities. Hydrite has identified several key metrics to help producers evaluate the efficiency of their corn oil extraction processes. The Hydri-Maize Index is a complimentary report available that allows producers to gain insight into their corn oil extraction process and how it stacks up to the rest of the fuel ethanol industry.

The percent oil analysis aims to quantify the efficiency of a producer’s corn oil extraction process. Specifically, we measure the percent of available corn oil in syrup (centrifuge feed) as it enters the centrifuge with the percent of available corn oil coming out of the centrifuge (heavy phase). This analysis measures how much of the available oil is extracted during the centrifugation process. This is also compared to the industry average.

Microscopic Analysis

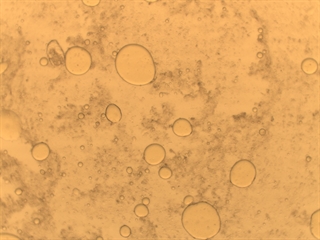

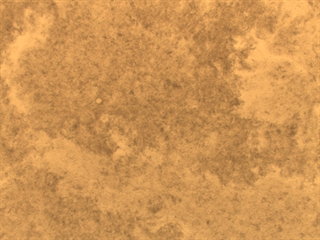

A microscopic analysis of both the centrifuge feed (left) and the heavy phase (right) is included as part of the Hydri-Maize Index. The microscopic analysis provides a visual representation of the system chemistry. Larger oil globules in the centrifuge feed, which are often the result of demulsification chemistry, are a predictor of highly efficient corn oil recovery. Available oil droplets in the heavy phase are an indication of demulsifier incompatibility.

Centrifuge Feed

Heavy Phase

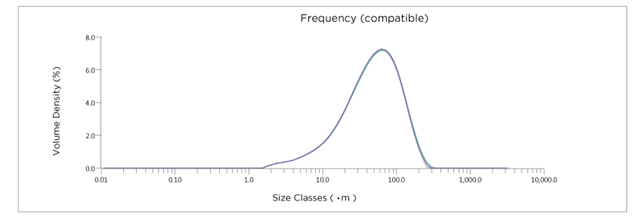

Particle Size Analysis

The availability of corn oil is influenced, in part, by the particle size of the syrup. A finer grind will expose more surface area to the demulsification chemistry and ultimately lead to greater system efficiency. The Hydri-Maize Index provides a particle size distribution of a syrup sample as well as a comparison to industry averages.

Contact us to request a Hydri-Maize Index when using our corn oil extraction process aids:

Contact Us

Want to know more about corn oil optimization? Contact us today!